Whether you are tired of your alloys getting damaged too easily or want to transform the look of your vehicle, powder coating is the best solution for aesthetic reasons as well as durability. Powder coating is a viable option for most wheels if you want to update your look or restore what you have. Call Waxman of Tristate Car Detailing Center to find out how powder coating works and if it is suitable for your wheels. The professional detailers provide the confidence and knowledge to help you make the right decision. Using the most advanced equipment and techniques, they offer a professional standard coating that preserves your car’s value.

Alloy wheel powder coating is a decorative finish for alloy wheels. It is a process that helps to improve the look of your car wheels while reducing the overall maintenance cost. Instead of paying for custom rims when they wear out, you can refinish them by opting for powder coating and make them look new again.

Powder-coating alloy wheels works by spraying a dry powder that settles on the surface. Once the powder is heated, it spreads out and cures to an even finish to coat the whole alloy wheel. This process results in a high-quality, durable surface that gives you a consistently fantastic look. Read on and learn more about powder coating and why car owners choose it for their alloy wheels.

What Is Alloy Wheel Powder Coating?

Alloy wheel powder coating is all about covering the surface of your rims with a dry polymer-based powder, which is mixed with curing additives, leveling agents, resin, flow modifiers, and pigments. The powder blend bonds to an electrostatically charged surface, and this is heat-cured in an oven or kiln. Under extreme heat, the powder melts and coats the wheels evenly. As the alloys are removed and cooled, the surface hardens and becomes smooth. Additional finishes and coating can also be applied to protect alloy wheels from scratches, contaminants, wash swirls, and UV light damage, making them look new for longer.

Related: How Much Does Powder Coating Your Car Wheels Cost?

What Are the Pros and Cons of Powder-Coating Alloy Wheels?

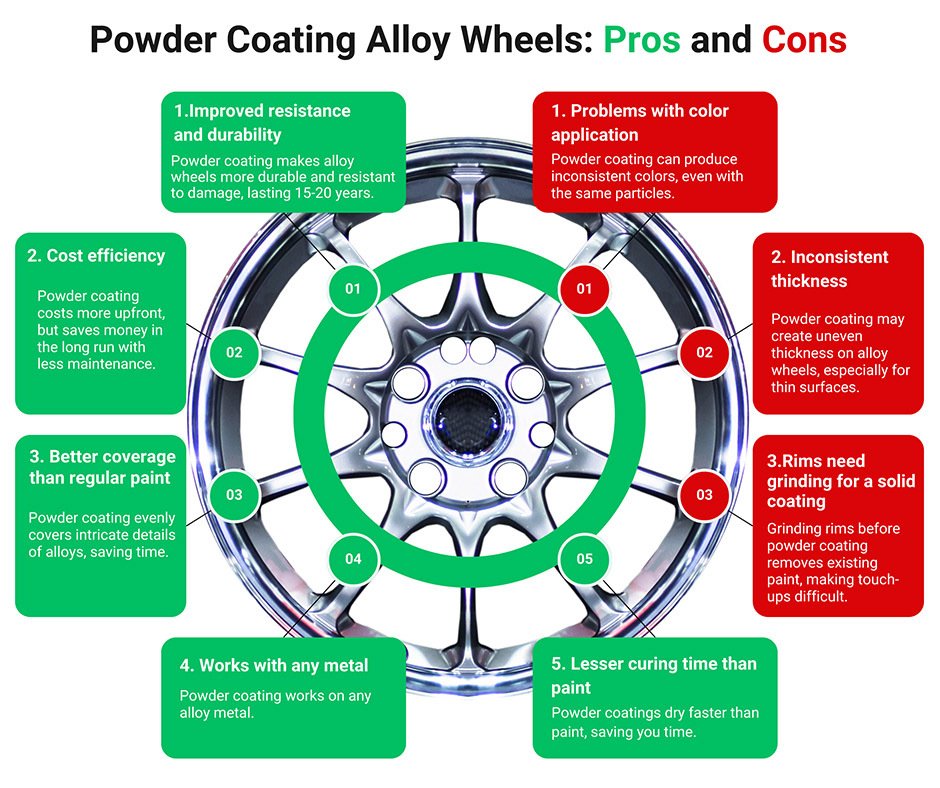

There are several pros and cons to powder coating your alloy wheels. However, the pros outweigh the cons, and you may benefit from having your alloy wheels powder-coated with the best detailer for a harder, more durable finish than a traditional paint respray.

The pros of powder coating alloy wheels for car owners are:

- Improved resistance and durability – As powder coating provides a thick, consistent layer of coverage for the alloys, it increases their resistance and durability, which helps them last longer. A high-quality alloy powder coating should last between 15 to 20 years. The non-porous surface also provides better protection from chipping, flaking, or corrosion.

- Cost efficiency – It may cost more than regular paint, but it does not require regular maintenance and helps car owners save a lot of money in the long run.

- Better coverage than regular paint – At times, alloys have intricate details that make it difficult to paint them or takes a long time. With powder coating, you can rest assured that every part is evenly covered without wasting time.

- Works with any metal – Powder coating can be applied on any metal surface when the alloys are brass, stainless steel, or aluminum and works great.

- Lesser curing time than paint – Painted wheels may take several hours to dry without heat, but powder coatings can be ready in as little as 10 minutes. They take less processing time and go through the drying and curing process faster. You can have your car back within no time.

Some cons of powder-coating alloy wheels include:

- Problems with color application – The baking process usually creates a consistent result, but you may face issues with the final tone or hue once the rims come out of the oven. It means you can encounter problems with cross-contamination, even when the same particles are applied to all the wheels.

- Inconsistent thickness – It often becomes tough to create a thin surface when powder-coating alloy wheels or you may not the same level of thickness all over. The thickness of the surface can be problematic for some wheels, especially when you want a thin surface on rims for a specific look.

- Rims need grinding for a solid coating – Rims are grinded before the powder coating so that the surface is workable for the baking process. It means the paint has to come off the wheels before the coating process can begin. If you already have a powder coat on that needs a touch-up, this prep work can become a real headache.

Powder coating is an effective solution for making your wheels look great. It is up to you to understand how it works, and how you can make the best of this approach.

How to Powder Coat Alloy Wheels – How Does It Work?

Here is a step-by-step guide on how a professional detailer will apply alloy wheel powder coating:

The Preparation Stage

The preparation stage is the most significant. It is because without proper prep work, achieving a high-quality finish is not possible, and it can also affect the outcome of powder coating and its durability. The whole wheel is removed from the car as it is a full refurbishment process. Then, it is thoroughly cleaned to ensure the alloy is free from all contaminants. A specialist alloy wheel cleaner and sandblaster are usually necessary to loosen stubborn particles and get rid of the trickiest grime.

The detailer will also remove flaws, imperfections, and sand abrasions or curb damage on the alloy surface manually. Next, the alloys are heated in a kiln or over to release any gases that could cause problems in the final finish.

Application of Base Coat

The alloy wheel is suspended in the paint booth, electrically charged, and sprayed with the base coat. A special spray gun is used to create a smooth foundation layer. Professional detailers know how to do it right. They use a sufficient amount of powder, keeping in mind its curing time to achieve desired results. Once the base coat is carefully applied, the alloys are placed back into the oven for about 20 minutes or until the powder begins to spread as a gel-like consistency and adheres across the surface.

Application of Clear Coat

After the alloys are removed from the oven, they are left to cool until they reach room temperature. Then, they are taken back to the painting booth for the clear coat. The clear coat is applied the same way as the base coat. The only difference is that it will appear white before it is baked. The rims are returned to the oven and baked for about 40 minutes. This process is also known as heat treating. Once the alloy is completely cooled, any hooks, tape, or plugs that were used during the coating process are taken out, and the wheels are fitted onto the vehicle.

Why Should I Choose Powder Coating?

If your wheels have sustained wear and tear or you want to change their color, powder coating is a great option. However, do your homework, search for the best service to get the desired outcome, and find out how it can benefit your vehicle and wheels.

Related: Ceramic Tint vs Regular Tint

At Waxman of Tristate Car Detailing Center, you can look forward to getting the best solution for your alloy wheels with tried and tested techniques. As the most top-rated and trusted service provider in Jersey City, NJ, you can easily get the custom look you want for your vehicle. They will help you understand how this process works and if the value of powder coating your wheels is worth the investment you make.