If your wheel rims are losing their shine or wearing out, powder coating may be the correct way to refinish them and make them look brand new. Powder-coated rims not only improve the appearance of your wheels but also give your vehicle a great finish and unique effect while lowering maintenance expenses. Waxman of Tristate Car Detailing Center provides you with the best services when it comes to powder coating wheels. Whether you want to go ahead with the process right away or learn its pros and cons, the experts guide you on what will work best for your wheels and how to keep them looking new for longer.

Powder coating has made alloy wheels more colorful and durable. It is a process that enhances the appearance of your wheels while reducing the general cost of keeping your vehicle in good shape. Refinishing your wheels with powder coating makes them look brand new when they appear worn out and it is cheaper than acquiring new custom rims. The pros and cons of powder-coating wheels may not apply to every driver, but they can help you decide if this custom look is suitable for your vehicle.

Powder Coating – What Is It?

Powder coating uses ground particles made of specific resin and pigments. These particles get electrostatically charged during spraying, which allows them to adhere to the rims. The wheels are baked in a high-temperature oven that makes the surfaces blend to produce a hard cure. The process results in a high-quality, long-lasting surface that is reliably fantastic.

Aluminum alloy wheels are usually finished in grey paint with a thick layer of lacquer to protect the relatively soft aluminum alloy from road damage. It makes the wheels almost look as if they have not been finished at all, and the silver-grey of the aluminum shows through, making it aesthetically pleasing without detracting too much from the form and color of the vehicle.

As car owners seek to make their vehicles look aesthetically pleasing and prevent wear and tear, alloy wheel powder coating allows them to do it right. Powder coating has become popular as it increases the durability of the outer surfaces at a reasonable cost. Powder coating has both pros and cons when applied to alloy wheels. Read on to find out the pros and cons of powder coating wheels and if it would work for you.

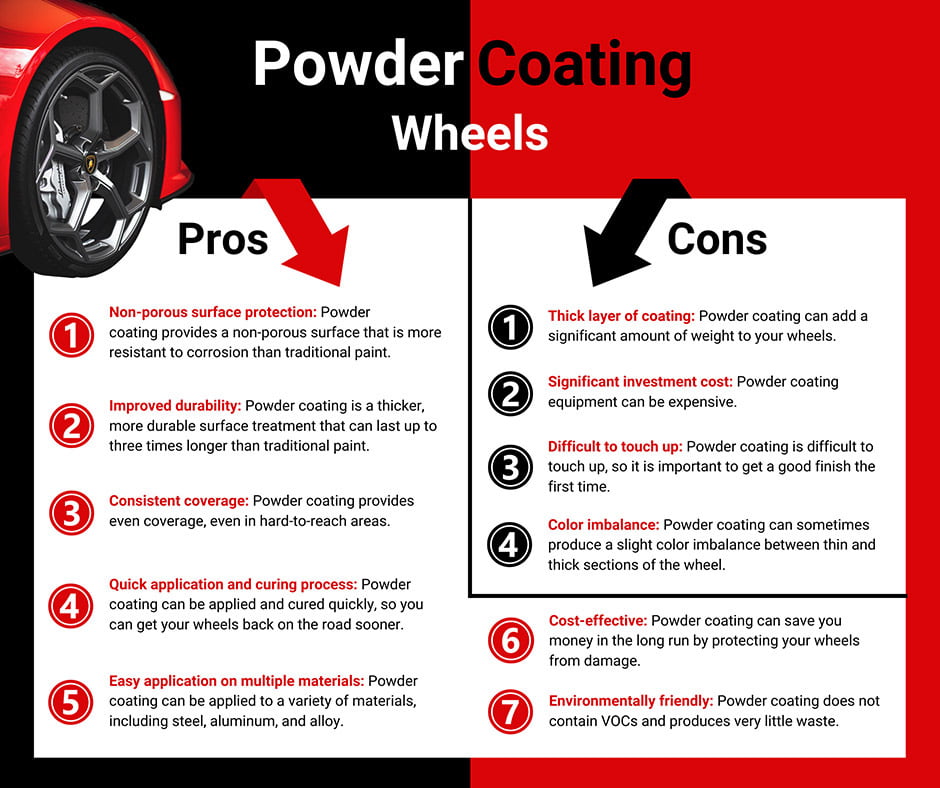

Pros of Powder Coating Wheels

Although there are several other ways to improve the general durability and appearance of the rims that require a new finish, rim powder coating has several advantages.

They include:

Non-porous Surface Protection

Even paint and lacquers allow small amounts of moisture to get them with time, passing through to the aluminum and corroding it from the inside. Powder-coated wheels do not suffer from the bubbling that other finishes succumb to with time.

Powder coating provides a non-porous, more durable surface on the rims that shields the wheels more than traditional paint. Your powder-coated rims can withstand even the most extreme conditions. You will come out of some unforgiven conditions with less overall damage than you would in other cases.

Improved Durability

Powder coating is a thicker, hard-wearing surface treatment that lasts three times more than normal paints and lacquered surfaces. As this process involves spraying particles onto the wheel rims and baking them in an oven at high temperatures, it bonds the coating really well to the surface, enhancing the product’s durability. When a thick layer is applied to the rims properly, they become highly resistant to outside forces, creating uniform, perfectly blended surfaces with a longer life.

Consistent Coverage

Powder coating outperforms liquid paint in terms of coverage. As it uses an electrostatic approach, the powder coating mix is attracted to the surface in an even layer, which results in consistent covering when baked. Combined with the curing process, it provides adequate coverage to even the most difficult-to-reach areas of the rim effectively. Also, there is no risk of drips and runs forming on the rim.

Quick Application and Curing Process

You don’t have to wait long for most powder painting tasks. With the wheels clean of grease and prepped, the actual process does not take much time, as there are only the application of the mix and curing operations to perform. While the traditional methods can take several hours, powder coatings can complete your rim in less time. The curing process is swift, resulting in a firm, even surface without the need for air drying. You can save time and get a brand-new look within hours.

Easy Application on Multiple Materials

The best thing about the powder coating technique is that it is a versatile solution that can be applied to several wheel materials. Most wheels are made of stainless steel, steel, or aluminum alloy, and a powder coating is ideal for them. Non-metal rim components, such as fiberboard or glass, may also benefit from this option.

Even though powder coating does not bond with chrome, it can be removed before the application. You can also have your car or truck accessories powered-coated before installing them in your vehicle. The material must be able to go through the heating process for a durable and smooth finish.

Cost Efficiency

Even though you may pay more for powder coating initially, it can help you save money in the long run. You don’t have to buy rims every time they start looking old. Powder coating makes them look brand new and protects them from scratches, dings, and dents. Using powder coating on old rims is much cheaper than buying new ones.

The average cost of doing a whole set of rims is between $400 and $700. Some providers may offer the service for less, but you need to ensure that you are working with a reliable and professional detailer and get a good-quality finish.

Environment Friendly

Many other products used for rims contain volatile organic compounds (VOCs) that not only harm your lungs if you inhale them but are also harmful to the ozone layer. Powder coating is environment-friendly as it does not contain harsh chemicals, thus reducing the risk of VOCs.

Also, it does not produce any waste or excess paint that is impossible to reuse after you are done painting the wheels. The extra powder can be recycled and used again without difficulty, making it a great option and one of the best ways to take care of your vehicle.

Cons of Powder Coating

With several benefits, there are also some disadvantages of powder coating.

A Thick Layer of Coating

Powder coating is not the best option if weight conservation matters to you. It is on the heavy side and goes on thick. If you have intricate detail on your wheel, the application of the mix may dull it down and fill small areas. Due to its thickness on the metal surface that can remove some of the definition of the wheel, it can lead to problems with your car types. It may also have a rough texture when it is finished.

Significant Investment Cost

It is not like spray painting, and the equipment can be expensive. In addition to the spray gun and spray area, powder coating also requires a curing oven. All this can substantially increase the investment cost. Also, the detailer may charge you more if there is nothing else to cover with the same color. Small batches are particularly expensive.

Powder coating wheels may be cost-effective, but the initial cost and the investment in coating equipment could be expensive and not affordable for everyone.

Difficult to Touch Up

Touch-ups are tough with powder coating. If you have powered-coated rims that need some reworking, it is better to have them cleaned and start afresh. It will be easier than trying to refresh small areas.

Color Imbalance

The coating tends to be of a pretty consistent thickness once it is cured, but thinner sections may appear a slightly different color than the thicker sections. You may notice the difference when the rimes are taken out of the oven. The process of baking produces a consistent product. There are times when recycled products get into what you are doing and may cause color imbalance.

Powder coating your wheels is a great alternative to conventional liquid coating methods and offers numerous benefits if you want to update your vehicle look or restore what you have. With better aesthetics, durability, and cost-efficiency, it is the ideal choice for many car owners, but it may not be the best option for every car owner for several reasons. You must go through its pros and cons if you are considering switching to powder-coated wheels before making up your mind.

Related: Is Ceramic Tint Really Worth It?

Visit Waxman of Tristate Car Detailing Center to learn more about powder coating and if it is the right option for your vehicle. The experts help you decide if the pros of this method will get the results you seek and offer the best value for the investment.